reduce our carbon footprint and limit our consumption of resources

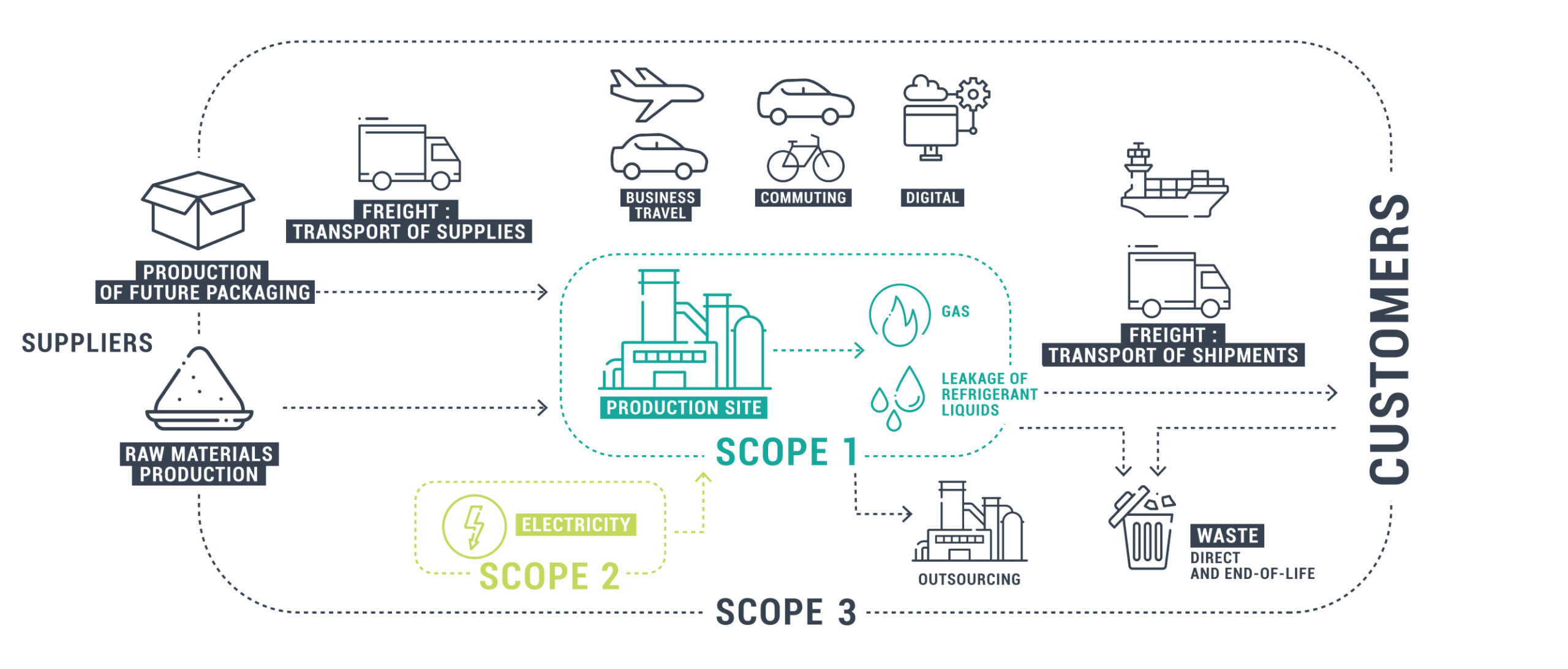

We have quantified this impact by carrying out a carbon assessment integrating scopes 1, 2 and 3, in order to identify the best courses of action for the future.

of gas consumption per ton of amino acids produced

invested in new technology

The Ecogreen process, to be commissioned in 2019, recovers heat from the circulating water of the cooling towers and returns it to the existing process, limiting the use of steam and reducing gas consumption.

water is a major issue

Our industrial process uses water taken from the natural environment (groundwater) as well as drinking water and discharges effluents (wastewater, cleaning water, purge water, etc.).

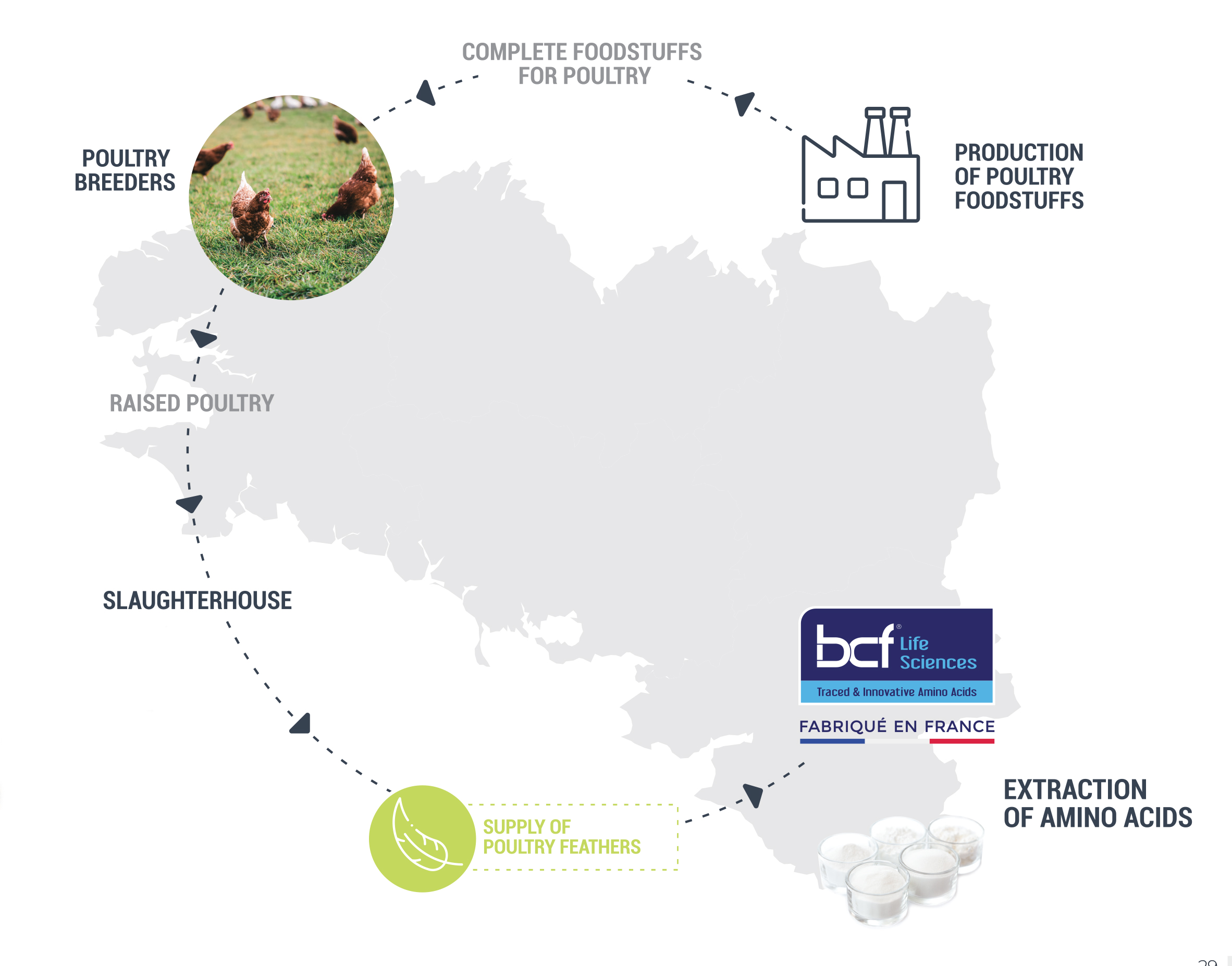

BCF Life Sciences, a pioneer in the circular economy built around the Breton poultry industry.

BCF Life Sciences is a major partner in the French poultry industry, which includes chick hatching operations, poultry farmers, poultry feed producers, and processing plants for whole or cut-up fresh poultry and poultry-based prepared meals, representing a total of 50,000 jobs in France in 2019.

The valorisation of co-products such as feathers represents one of the links in the chain’s value creation. In 2020, in the context of the COVID-19 crisis, BCF Life Sciences’ activity was recognised by the French government as “necessary for the proper functioning of the nation”.

of the waste generated was recovered

Preserving resources also means reducing and recycling waste. BCF Life Sciences has a programme to optimise and recover waste, either internally or externally by relying on dedicated service providers to process it.

A waste sorting programme is in place on the site (wood, cardboard, ferrous and non-ferrous metals, ordinary industrial waste).